FEATURED WORK

The NAFEM Show

Autodesk University

Our Work

We help the world’s leading associations and exhibitors build meaningful relationships with customers through memorable experiences.

-

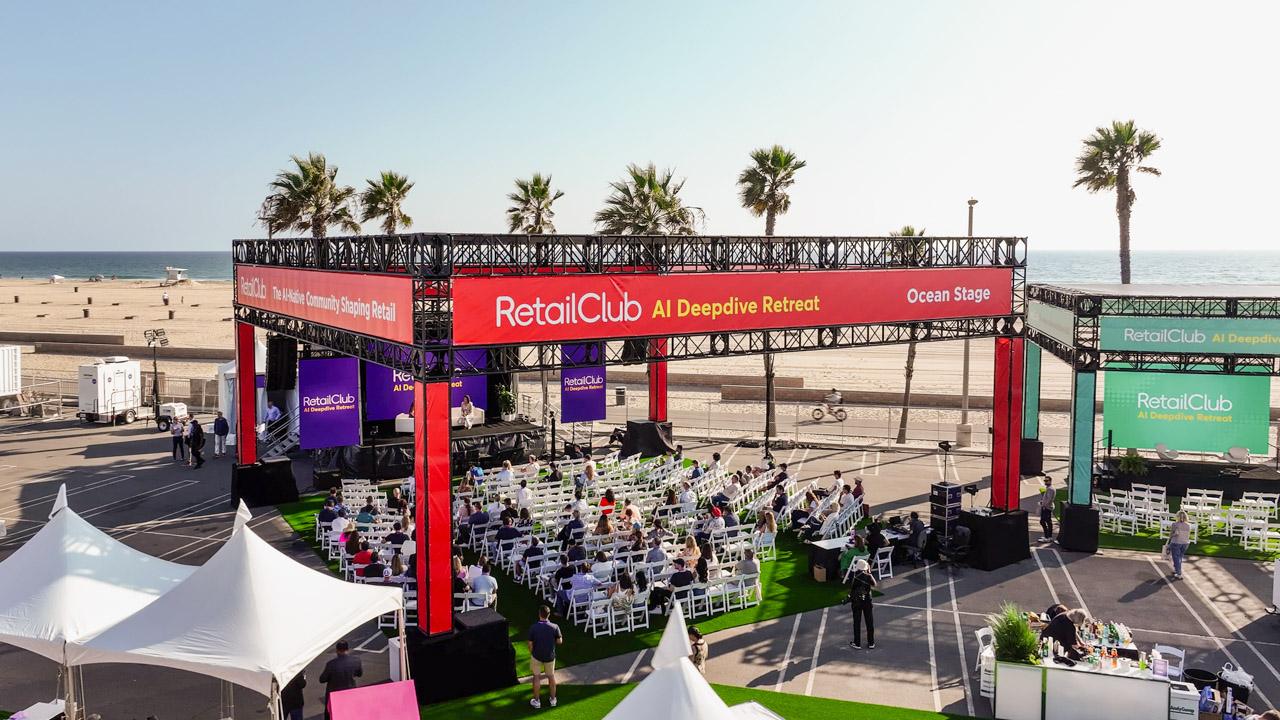

RetailClub: AI Deepdive Retreat

RetailClub: AI Deepdive Retreat How Studio Blue transformed a parking…

-

AUSA

Commemorating the U.S. Army’s 250th Anniversary

-

Shoptalk

How to Create the Perfect Alchemy for Retail Industry Innovation.

-

ASCO

Evolving Education: How ASCO 2025 Created a Connection-Driven Experience

-

LAV

Creating a Best in Glass Exhibit

-

The NAFEM Show

All Signs Point to WOW

-

Autodesk University

How A Redefined Attendee Journey Scored an A+

-

Hard Rock

Rock Star Presence Across Multiple Shows

-

RE+ 2024

Enhancing Attendee Navigation

-

Groceryshop

Setting The Stage With AV Solutions

-

AIA

Building Connections