Resource Collections

Best practices, planning tips, checklists, insights, and expert guidance for planners, exhibitors, and everyone who makes live events happen.

19 resources

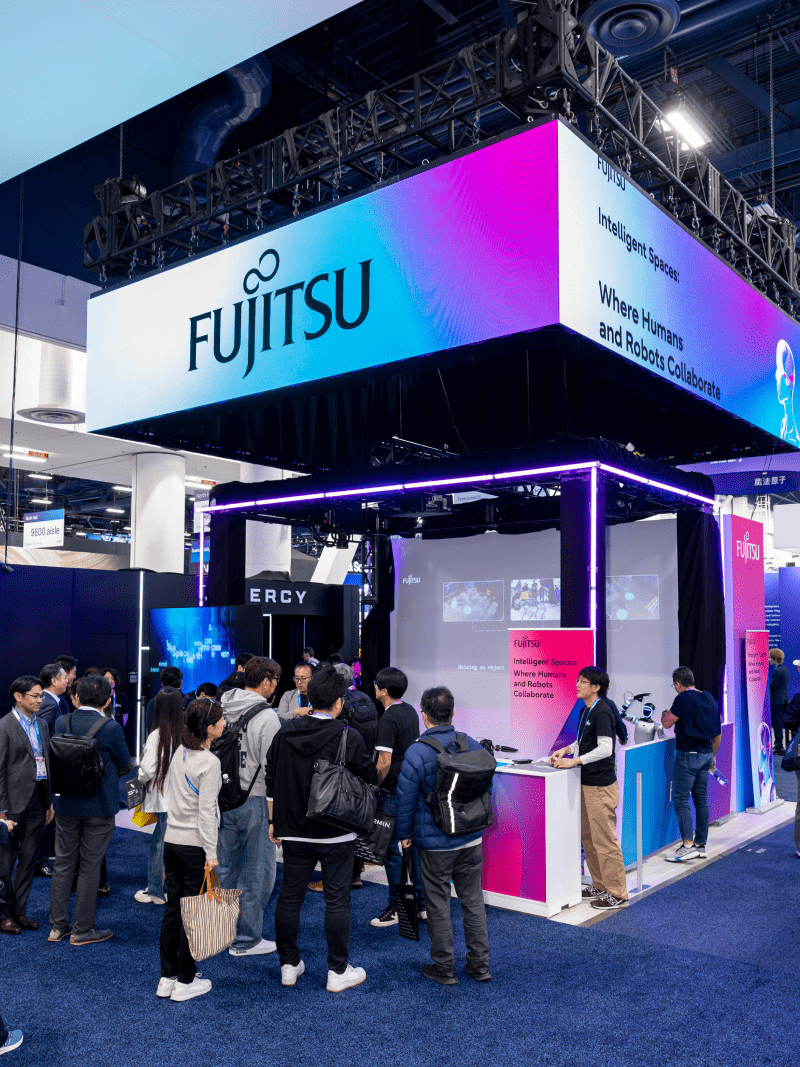

Exhibiting made easier

Tools to simplify every step of your exhibiting process: planning, budgeting, designing, troubleshooting, measurement, ROI, and more.

4 resources

Show manager tools

Everything you need to plan conferences and events for today’s audiences.

5 resources

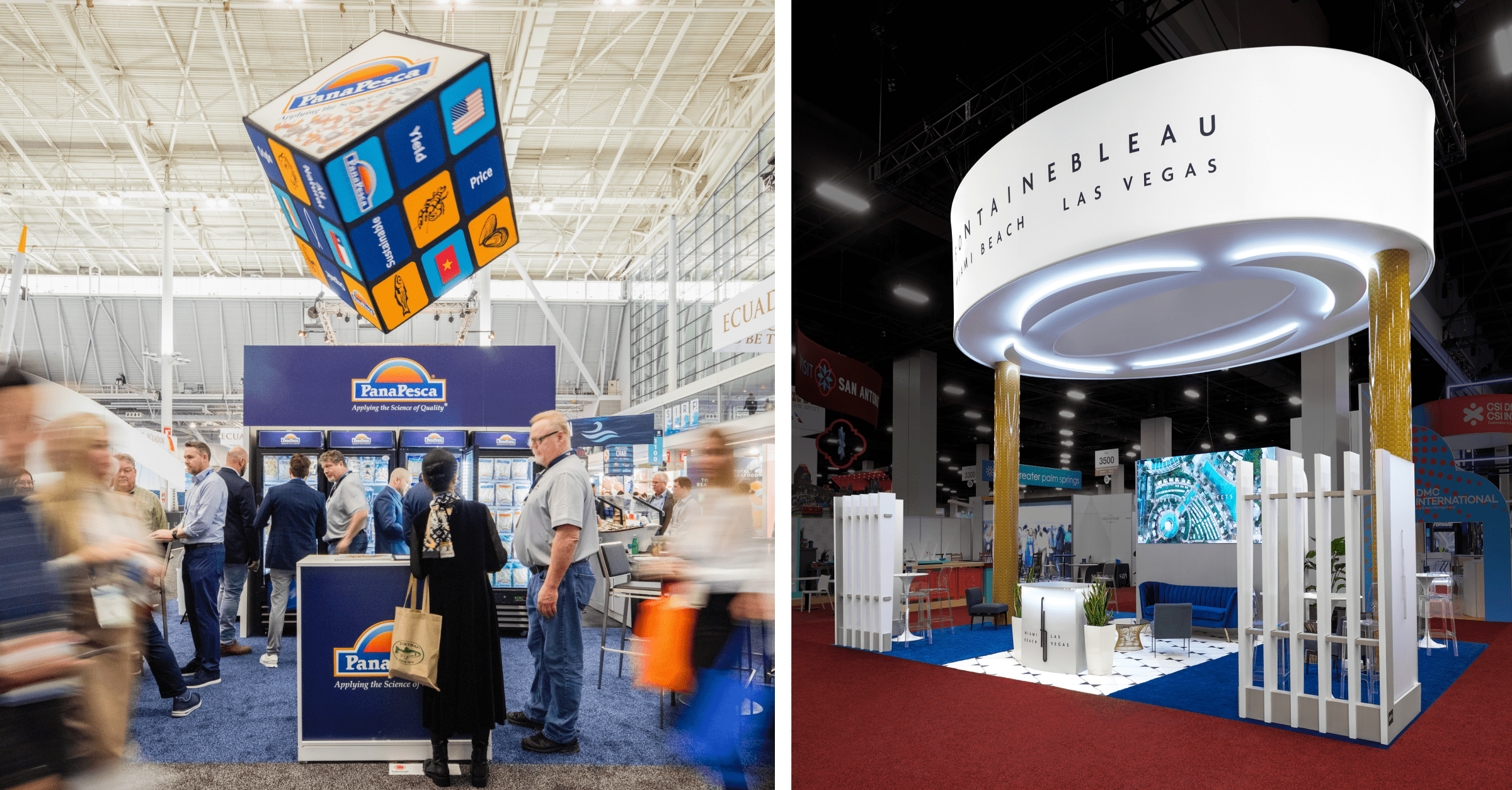

Everything you need for planning live events

Step-by-step guidance for planning your next event or exhibit, from engaging attendees to experiential tech to sustainability and sponsorship.

14 resources

Set the stage with AV

Behind-the-scenes insights from experts to deliver content, plan production budgets, elevate events, stay on trend, engage audiences, and more.

Resource Library

The latest news, insights, and trends in live events, exhibits, and experiences.